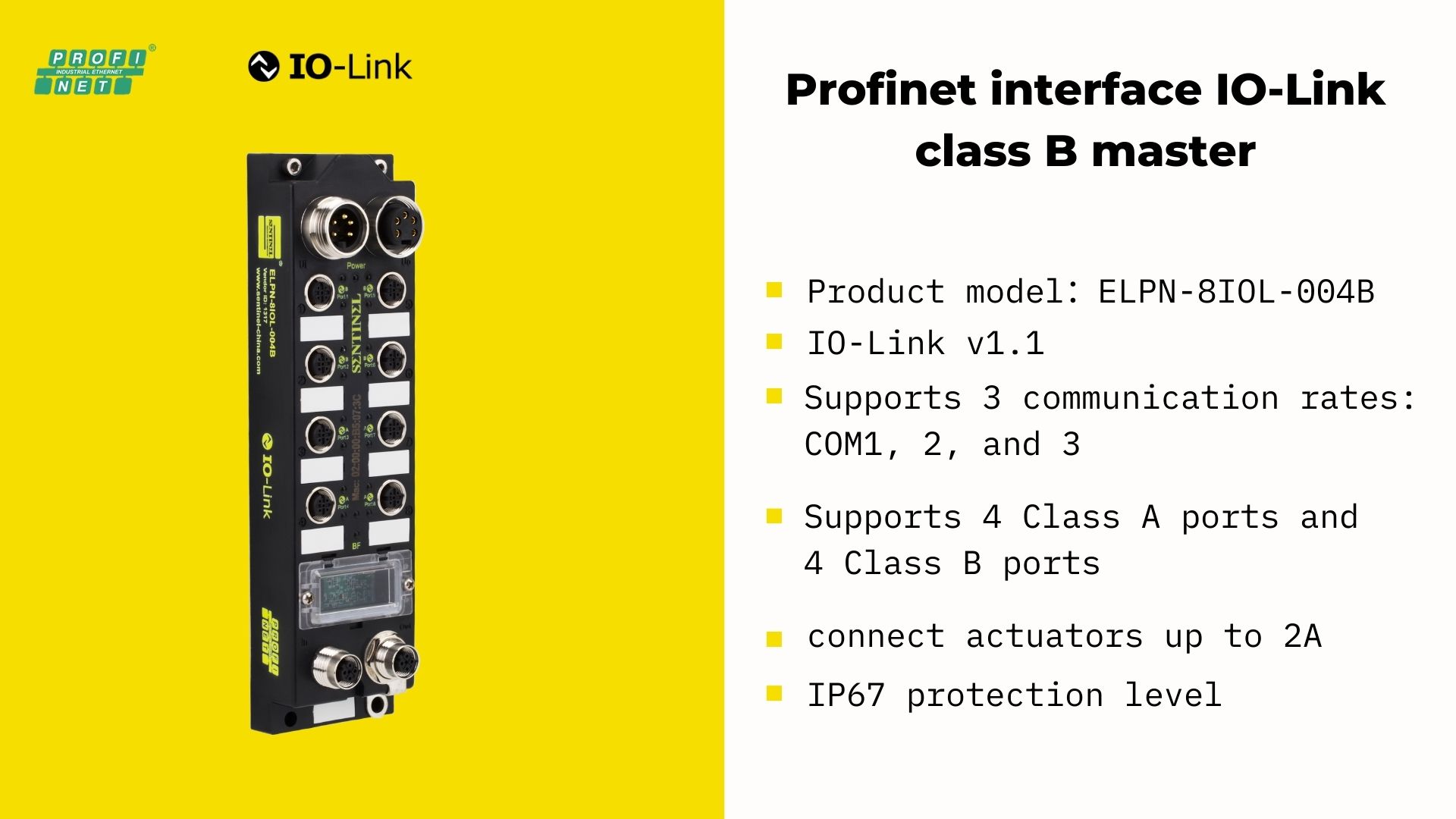

New Product Release | IO-Link Class B Master Station

SENTINEL recently launched a new IO-Link product, the Class B master station, dedicated to continuous improvement and innovation. It is designed with a high-strength glass fiber-reinforced plastic housing and metal connectors to achieve higher stability and durability. The product is fully sealed with epoxy resin, providing excellent resistance to impact and vibration, and has an IP67 protection rating, ensuring stable operation in various harsh environments. It is powered by a 2-way 7/8" power interface and features 2 Ethernet interfaces (M12 D code, built-in Ethernet switch), 4 A-ports + 4 B-ports (M12 A code) IO-Link communication interface. Currently, it supports the Profinet protocol, with ongoing research and development of other protocols.

Advantages of B-class ports

Class A port

-

Class A ports use a 5-pin M12 connector. Pins 1 and 3 provide a 24V DC power supply for IO-Link devices. Pin 4 is used for IO-Link signal transmission. Pins 2 and 5 are empty.

-

The maximum load current of a single port can reach 2A, but the sum of the four ports must not exceed 4A.

B-class port

-

B-class ports use a 5-pin M12 connector. Pins 1 and 3 provide a 24V DC power supply for IO-Link devices. Pin 4 is used for IO-Link signal transmission. Pins 2 and 5 provide power for the load, supplying power to the device (e.g. valve island).

-

The maximum load current for a single port can reach 2A, but the total of 4 ports must not exceed 4A.

Therefore, Class B ports not only have all the functions of Class A, but also have innovations in the aspect of load power supply. They can directly output load power to devices without the need for additional load power supplies, making wiring simpler and installation more convenient.

Advantages of IO-Link

IO-Link can be integrated into any automation system that uses sensors/actuators. The advantages of IO-Link are:

Data Storage

- When replacing the sensor, the IO-Link master station will automatically and quickly write the parameters of the replaced IO-Link sensor into the new sensor. The equipment can restart and operate without manual intervention. This not only saves valuable time but also minimizes the possibility of human errors.

Remote Configuration and Monitoring

- Equipment and sensor parameters can be easily changed remotely according to the needs, making it easier to reconfigure devices in hard-to-reach locations.

- You can remotely monitor sensor outputs and status alerts in real-time, helping you quickly identify and resolve issues before they cause downtime.

Diagnostic Features

- Smart sensors equipped with IO-Link can communicate their own status to the PLC via an IO-Link master. You will know if the sensor needs to be replaced, maintained, or if it encounters an error. This allows you to optimize machine maintenance.

Cost saving

- In addition to saving time, IO-Link can also reduce overall system costs. Since IO-Link does not require any special or complex wiring, material costs are also lower. You can use the most common unshielded cables, even for analog signals, which reduces the variety of cables you need to purchase.

Flexible adaptation to different application scenarios

While IO-Link may not be the first choice for big data and high-speed applications, it performs exceptionally well in the vast majority of factory automation environments and can meet a wide range of sensor and actuator requirements.

To learn more about IO-Link master and slave products, please contact the sales team or Email us: sales@sentinel-china.com. We have a professional technical team to provide you with detailed product introduction and solutions.