SENTINEL: Consistency of Quality for Ten Years

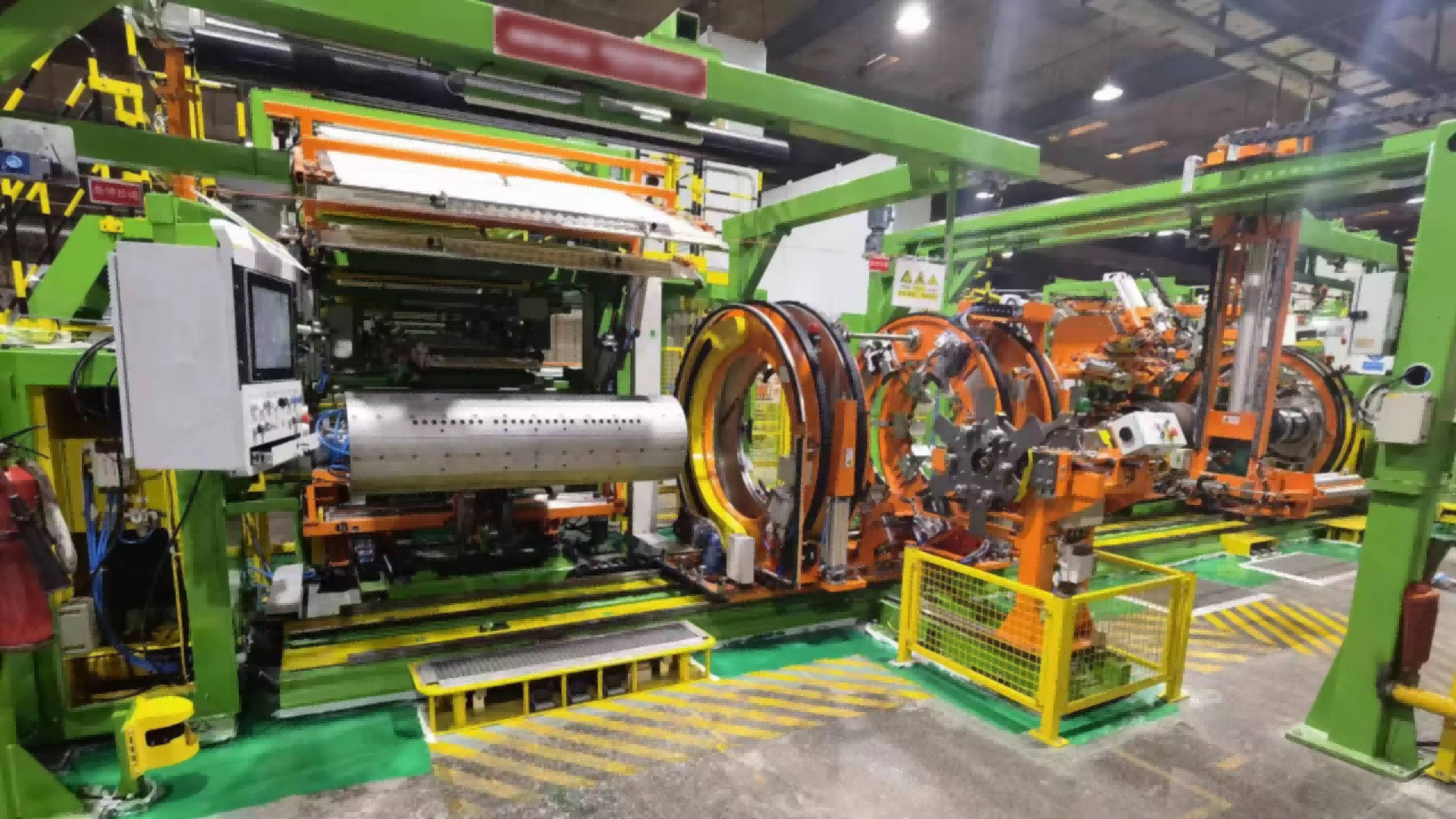

I am a technical engineer of a professional full-steel radial tire manufacturing company. The first time I used SENTINEL's product was in 2013, which was motivated by the upgrade of the three-drum molding machine equipment. In order to improve product quality and increase production capacity, it was necessary to install high-precision position measurement sensors to achieve closed-loop automation control. Due to it being an equipment modification project, the installation space for the sensors was limited. SENTINEL technical personnel personally came to the site and worked with us to develop a plan, successfully completing the equipment modification project.

Although we use a small quantity, SENTINEL is able to serve customers so diligently, which greatly touches us! SENTINEL's encoder counts accurately and reads feedback data precisely. Over the course of 10 years, there have been no product quality issues. It plays a crucial role in our product quality and output.

When I saw the call for essays for SENTINEL's 15th anniversary celebration, it reminded me of the past ten years. However, it was only when I logged on to SENTINEL's official website that I realized the rich array of industrial Ethernet products and high-tech sensors that were now presented before me. SENTINEL's growth has impressed me, but at the same time, I feel somewhat regretful for knowing so little about their products. I hope that SENTINEL will continue to enhance and improve its market promotion of the products, as we are eagerly looking forward to understanding and using more of SENTINEL's products.

The growth and achievements of SENTINEL over the past 15 years have convinced me that domestic brands are our trump card. Localization is our future.